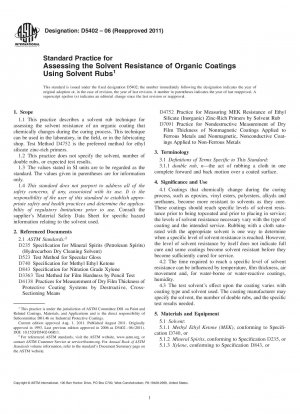

ASTM D5402-06(2011)

Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs

- Standard No.

- ASTM D5402-06(2011)

- Release Date

- 2006

- Published By

- American Society for Testing and Materials (ASTM)

- Status

- Replace By

- ASTM D5402-15

- Latest

- ASTM D5402-19

- Scope

Coatings that chemically change during the curing process, such as epoxies, vinyl esters, polyesters, alkyds and urethanes, become more resistant to solvents as they cure. These coatings should reach specific levels of solvent resistance prior to being topcoated and prior to placing in service; the levels of solvent resistance necessary vary with the type of coating and the intended service. Rubbing with a cloth saturated with the appropriate solvent is one way to determine when a specific level of solvent resistance is reached. However, the level of solvent resistance by itself does not indicate full cure and some coatings become solvent resistant before they become sufficiently cured for service.

The time required to reach a specific level of solvent resistance can be influenced by temperature, film thickness, air movement and, for water-borne or water-reactive coatings, humidity.

The test solvent's effect upon the coating varies with coating type and solvent used. The coating manufacturer may specify the solvent, the number of double rubs, and the specific test results needed.

1.1 This practice describes a solvent rub technique for assessing the solvent resistance of an organic coating that chemically changes during the curing process. This technique can be used in the laboratory, in the field, or in the fabricating shop. Test Method D4752 is the preferred method for ethyl silicate zinc-rich primers.

1.2 This practice does not specify the solvent, number of double rubs, or expected test results.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Consult the supplier's Material Safety Data Sheet for specific hazard information relating to the solvent used.

ASTM D5402-06(2011) Referenced Document

- ASTM D235 Standard Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

- ASTM D3363 Standard Test Method for Film Hardness by Pencil Test

- ASTM D4138 Standard Test Methods for Measurement of Dry Film Thickness of Protective Coating Systems by Destructive Means

- ASTM D4752 Standard Test Method for Measuring MEK Resistance of Ethyl Silicate (Inorganic) Zinc-Rich Primers by Solvent Rub

- ASTM D523 Standard Test Method for Specular Gloss

- ASTM D7091 Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals

- ASTM D740 Standard Specification for Methyl Ethyl Ketone

- ASTM D843 Standard Specification for Nitration Grade Xylene

ASTM D5402-06(2011) history

- 2019 ASTM D5402-19 Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs

- 2015 ASTM D5402-15 Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs

- 2006 ASTM D5402-06(2011) Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs

- 2006 ASTM D5402-06 Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs

- 1993 ASTM D5402-93(1999) Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs